cadblu

Well-Known Member

- Thread starter

- #1

Ok, we get it. A fully equipped and capable paint shop with proper environmental / temperature/ humidity/ filtration controls can run upwards of $500M. I admire Slate for their design decision up front to use molded composite body panels not requiring paint, and highly suitable for wraps.

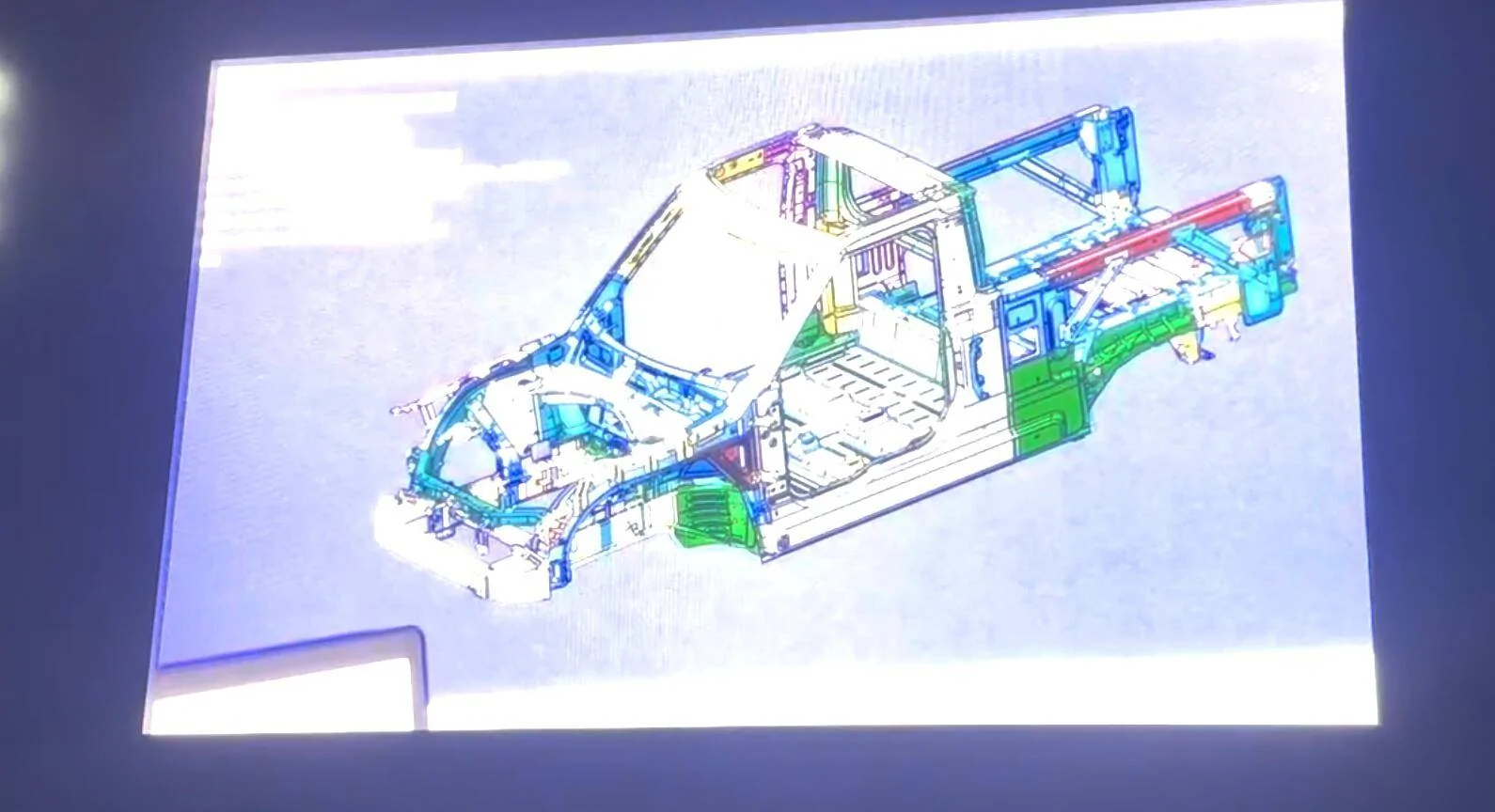

But the problem lies with all the steel underpinnings, frame, and structural components that need durable protection, e.g. primer, paint, coatings, etc. Where is that getting done? I’m sure engineering has already figured this out, perhaps all subassemblies will be sourced with paint and coatings, or it will be done in-house under small paint hoods. Hopefully as more details are revealed we will get insight into their strategy. Your comments are appreciated.

But the problem lies with all the steel underpinnings, frame, and structural components that need durable protection, e.g. primer, paint, coatings, etc. Where is that getting done? I’m sure engineering has already figured this out, perhaps all subassemblies will be sourced with paint and coatings, or it will be done in-house under small paint hoods. Hopefully as more details are revealed we will get insight into their strategy. Your comments are appreciated.