-

👉 Slate Reservations Tracking List: Add Your Slate Reservation 📊

AnnDee4444

New Member

Depending on how it's designed, a De Dion suspension could use the same struts as the front suspension.

Related:

Why The Slate EV’s Unconventional Rear Suspension Makes Perfect Sense

https://www.theautopian.com/why-the-slate-evs-unconventional-rear-suspension-makes-perfect-sense/

Related:

Why The Slate EV’s Unconventional Rear Suspension Makes Perfect Sense

https://www.theautopian.com/why-the-slate-evs-unconventional-rear-suspension-makes-perfect-sense/

Ewwgas

Active Member

This would be a poor design for a few reasons, most obvious to me is the camber curve when the truck is loaded.If Slate wants to use as much part commonality as possible, why not just go struts all around and use the same suspension front and back? Use a suspension link in place of the tiered for the rear hubs. An IRS should easily handle a 1,400 pound payload.

Pickup box intrusion maybe?

Also You would also get bump steer in the back, which would be sktecy. You would also have a weird axis of rotation that would be flat if both front and rear matched, then as the roll center moves around during braking and cornering the tendency to oversteer or understeer would randomly switch depending, the truck would be super unpredictable.

Slate would need to add features to the strut for it to mount and pivot through its rage of motion, on the front it would be fixed to steering knuckle and on the rear the lower mount would need to pivot. Then you would have a different spring rate for the rear, so you would need different shock valveing, also it would be a waste of engeering to try to match the packaging... I think different shocks f/r is the correct approach to save money.Depending on how it's designed, a De Dion suspension could use the same struts as the front suspension.

Ewwgas

Active Member

Sure, the lighting has IRS, but not an identical front and rear MacPherson like you suggested. The MacPherson has a pretty aggressive camber curve. Also it has a built in king pin angle designed to be steered. You can't really use it on the back.

With the F/R MacPherson set up, The shocks would need to be vavled different f/r. Slate would have to order them as 4 shocks. Front left, right, rear left, right. 4 different shock part numbers for 4 shocks.

To me it looks like Currently they have front left, front right, and rear. 3 shock PNs for 4 shocks.

With the F/R MacPherson set up, The shocks would need to be vavled different f/r. Slate would have to order them as 4 shocks. Front left, right, rear left, right. 4 different shock part numbers for 4 shocks.

To me it looks like Currently they have front left, front right, and rear. 3 shock PNs for 4 shocks.

AnnDee4444

New Member

Absolutely it's a better design with different parts front & rear. But it's still technically possible for them to be the same, even when mixing IFS & DeDion. I doubt this has been done by a manufacture in the last 80+ years though.Slate would need to add features to the strut for it to mount and pivot through its rage of motion, on the front it would be fixed to steering knuckle and on the rear the lower mount would need to pivot. Then you would have a different spring rate for the rear, so you would need different shock valveing, also it would be a waste of engeering to try to match the packaging... I think different shocks f/r is the correct approach to save money.

FWIW: spring/damping rates are only a piece of the equation. Motion ratio/ride frequency/load capacity/etc. are of great importance.

Ewwgas

Active Member

I agreeAbsolutely it's a better design with different parts front & rear. But it's still technically possible for them to be the same, even when mixing IFS & DeDion. I doubt this has been done by a manufacture in the last 80+ years though.

FWIW: spring/damping rates are only a piece of the equation. Motion ratio/ride frequency/load capacity/etc. are of great importance.

Driven5

Well-Known Member

I realize this is an 'older' thread, as much as can be on this young site, but wanted to address it anyway. It's also a shame that the OP apparently decided to delete most of their post for some reason, because this is actually a good question worth discussing. I'm not sure if there was more to it than can be seen in the quotes, but here goes:

Anybody who thinks struts in the rear are necessarily geometrically problematic, especially from a driver standpoint, has obviously never driven a Porsche Boxster or Cayman in anger. Well executed rear strut geometry would not not inherently instigate sketchy bump steer, weird axis of rotation, or random dynamic reversals to make handling unpredictable. Note that the Porsches also only use 2 strut part numbers on a car. One for the fronts, and one for the rears. The struts at both ends are the same left to right.

While perhaps not 'ideal' from a performance standpoint, the truck could easily be made entirely competent from a dynamic standpoint, even if the only component difference between the front and rear suspensions were the damper valving, springs, toe links replacing the tie rods, and probably some minor geometric alterations through only the chassis mount positions. It would also be incredibly economical. So why not do so?

There is an argument to be made about camber gain under load, but even then struts actually tend to have pretty mild camber curves. So actually that wouldn't be the end of the world. Camber doesn't kill tires nearly as much as toe. The biggest problem from this would be a handful of fringe use cases that spend like half of their time lightly loaded, and half of their time heavily loaded. Most people who would only occasionally have limited duration extreme opposite loading swings should have little long-term tire tire effects, as long as the static camber was set for their use case... And considering the lift/drop suspension options, they'll probably have to (or at least should) include sufficient factory camber adjustability anyways.

The OP appears to have actually hit on the biggest problem with rear struts in their quoted "Pickup box intrusion maybe?" thought... Struts are terrible for packaging anything more than a drivetrain between them. They have to pass inboard of the tire, and thus narrow the potential width between the wheel wells. They also extend substantially taller than the tire, and further narrow the available space up there, thanks to the width from the springs. This also isn't as bit of a deal on the front, where the wheel wells need to be sized for full-lock steering too, but in the back would be a big hit on cargo and/or passenger space.

I do believe that DeDion is easily one of the most underrated suspension types, and think it was a great call to use it here.

Anybody who thinks struts in the rear are necessarily geometrically problematic, especially from a driver standpoint, has obviously never driven a Porsche Boxster or Cayman in anger. Well executed rear strut geometry would not not inherently instigate sketchy bump steer, weird axis of rotation, or random dynamic reversals to make handling unpredictable. Note that the Porsches also only use 2 strut part numbers on a car. One for the fronts, and one for the rears. The struts at both ends are the same left to right.

While perhaps not 'ideal' from a performance standpoint, the truck could easily be made entirely competent from a dynamic standpoint, even if the only component difference between the front and rear suspensions were the damper valving, springs, toe links replacing the tie rods, and probably some minor geometric alterations through only the chassis mount positions. It would also be incredibly economical. So why not do so?

There is an argument to be made about camber gain under load, but even then struts actually tend to have pretty mild camber curves. So actually that wouldn't be the end of the world. Camber doesn't kill tires nearly as much as toe. The biggest problem from this would be a handful of fringe use cases that spend like half of their time lightly loaded, and half of their time heavily loaded. Most people who would only occasionally have limited duration extreme opposite loading swings should have little long-term tire tire effects, as long as the static camber was set for their use case... And considering the lift/drop suspension options, they'll probably have to (or at least should) include sufficient factory camber adjustability anyways.

The OP appears to have actually hit on the biggest problem with rear struts in their quoted "Pickup box intrusion maybe?" thought... Struts are terrible for packaging anything more than a drivetrain between them. They have to pass inboard of the tire, and thus narrow the potential width between the wheel wells. They also extend substantially taller than the tire, and further narrow the available space up there, thanks to the width from the springs. This also isn't as bit of a deal on the front, where the wheel wells need to be sized for full-lock steering too, but in the back would be a big hit on cargo and/or passenger space.

I do believe that DeDion is easily one of the most underrated suspension types, and think it was a great call to use it here.

AZFox

Well-Known Member

Is the De Dion tube (crossmember) an axle? If so there are three axles because the half-shafts are axles.I mean, trucks should have solid axles right? So good for them for using one.

Driven5

Well-Known Member

One word can have multiple meanings, and multiple words can have the same meaning. That's how you can have axles inside the axle on one axle, and axles with no axle on the other axle. Isn't English* grand?

* And that's even before getting into the different Englishes.

* And that's even before getting into the different Englishes.

Last edited:

Trace26

Well-Known Member

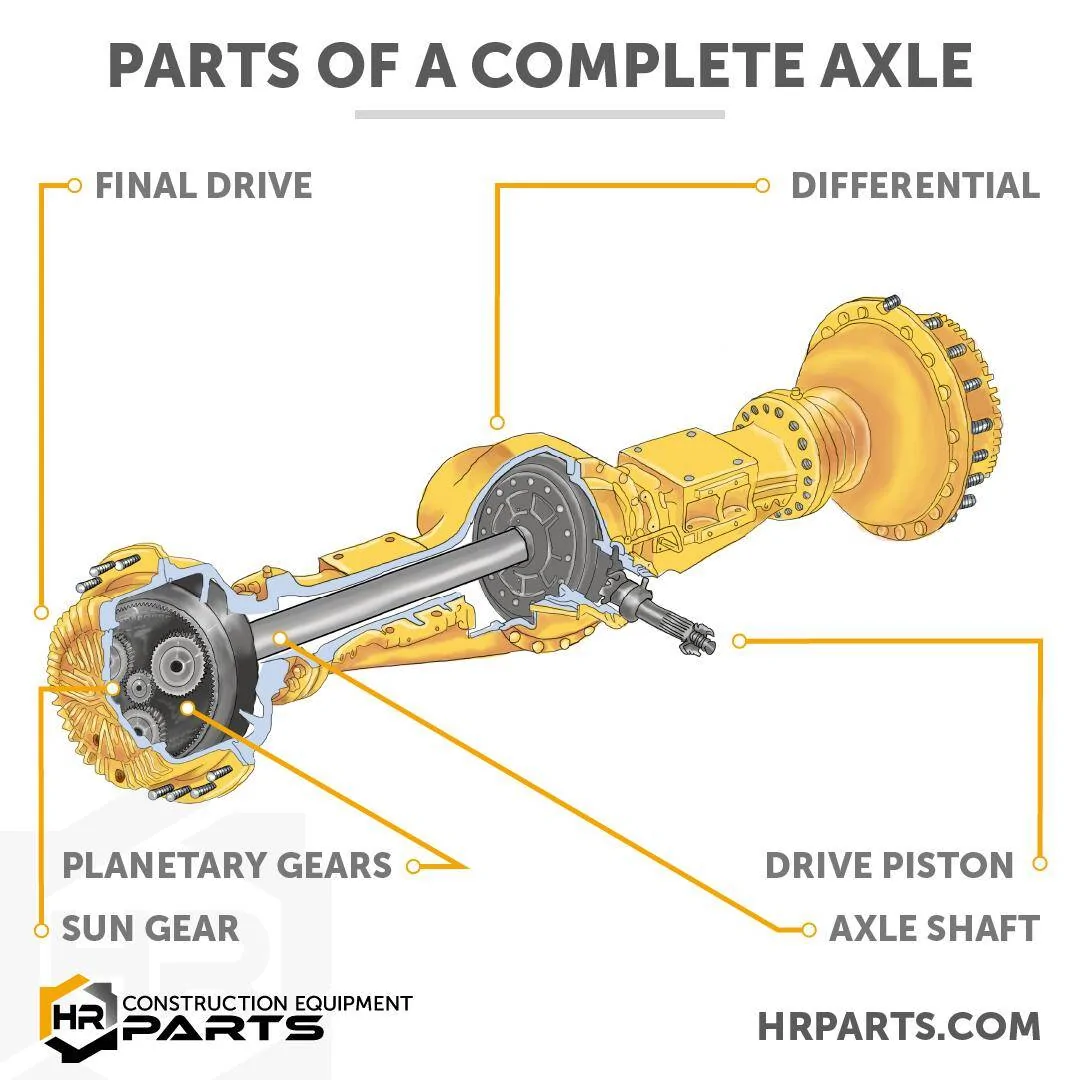

On a normal axle the axle shafts are inside the axle housing(tube), on the DeDion the axle shafts are outside the tube.Is the De Dion tube (crossmember) an axle? If so there are three axles because the half-shafts are axles.

The main difference is the differential is on the body of the truck (DeDion) vs in the center of the axle tube.

AZFox

Well-Known Member

I queried AI. Here's the summary of the answer:

In summary, while the de Dion tube functions similarly to a beam axle in terms of maintaining wheel alignment and suspension geometry, it is not typically called an axle in the conventional sense due to its lack of involvement in power transmission. Instead, it is more accurately described as a suspension beam or de Dion tube.

Trace26

Well-Known Member

The AI isn't wrong, the Dion tube is not an axle just like the axle housing isn't an axle on your traditional setup.

In both situations we are talking about the full assembly.

In both situations we are talking about the full assembly.