Tran

Well-Known Member

- Thread starter

- #1

https://insideevs.com/news/758345/slate-no-gigacasting-reason

The Slate Truck Won't Use Gigacasting. Here's Why It Doesn't Need It

Slate is all about reducing costs by reducing complexity, so why isn't it using Gigacasting?

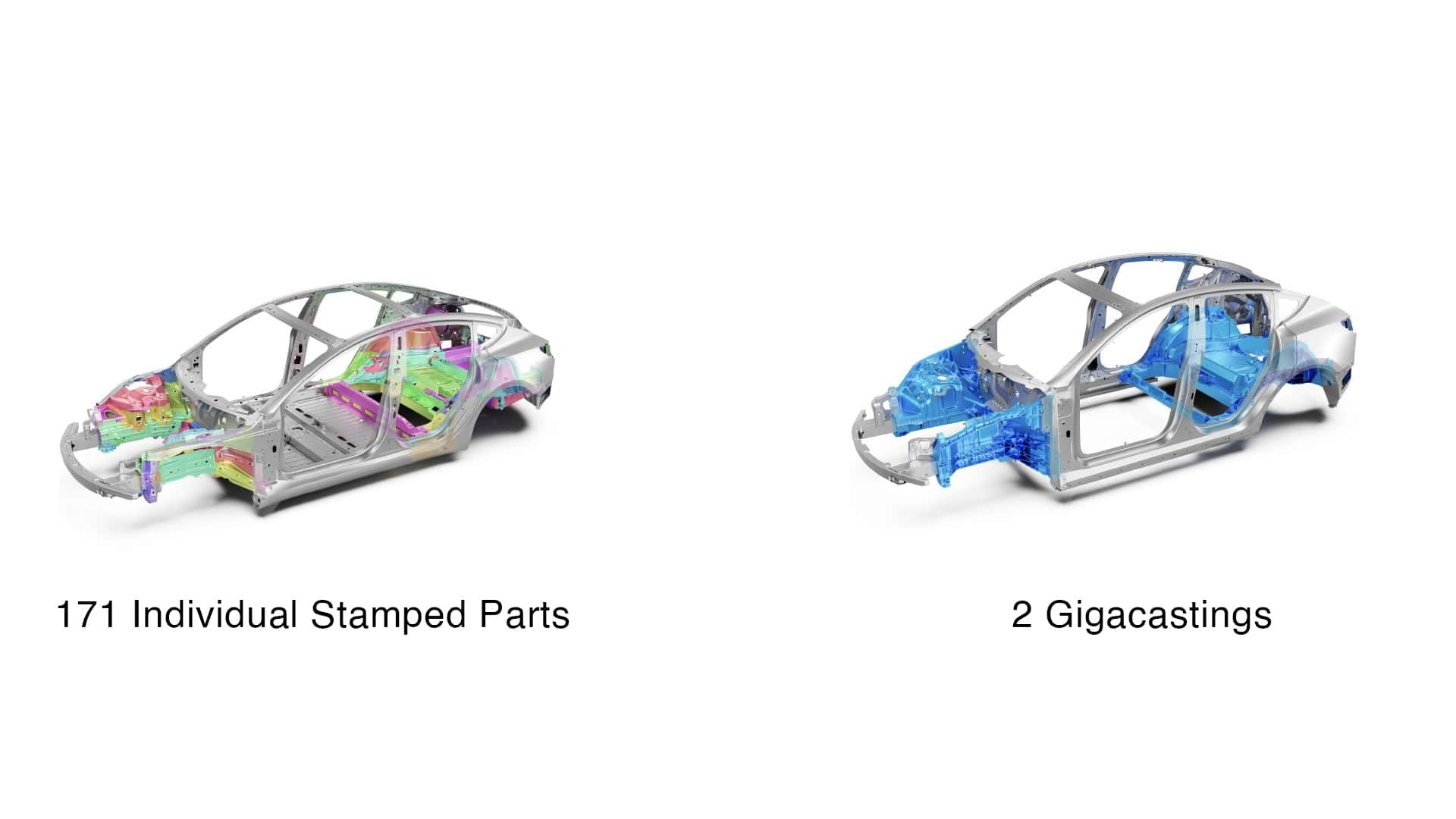

A car is built using a ton of stamped parts. To create these parts, a sheet of metal is fed into a machine that sandwiches it between a die and squeezes it until it forms a specific shape. This is great for smaller parts, but when you're building something larger (like the underpinnings of a vehicle), these pieces may need to be fastened together using rivets or welding.

Gigacasting, on the other hand, is taking molten metal and using a High-Pressure Die Casting (HPDC) machine to force the liquid metal into a mold. Tesla pioneered this technology and remains arguably its most vocal proponent, but the rest of the auto industry is rapidly chasing it too.

It allows for the creation of complex metal parts without the need to manually fasten each individual stamped part one by one. In Tesla's case, gigacasting allowed Tesla to eliminate 370 parts from the Model Y, all while reducing weight by 10% and improving efficiency.

171 stamped parts and 1,600 welds were eliminated by the use of two parts created by Gigacasting.

One key metric in automotive manufacturing is cost per minute. That figure is the time it takes a worker or piece of machinery to change the form, fit, or function of a vehicle. You know the saying "time is money"? It's extremely true in manufacturing and is something that automakers are willing to pay industrial engineers big bucks to cut down on.

Gigacasting reduces that cost significantly by optimizing equipment (think reducing the number of robots needed to assemble panels or welders to fasten them together), factory space, and even enabling waste to be easily recycled.

That's the good, but what about the bad? Well, that all comes down to cost—and that's where Slate looked at the tech and shook its head

"Gigacasting takes out complexity in parts but adds complexity in engineering and cost," a Slate spokesperson told InsideEVs. "Slate engineering and manufacturing focused on taking out what’s unnecessary and delivering a radically affordable vehicle."

Translation: We don't need a fancy metal-squirting machine to solve a problem we didn't already have.

Slate says it can justify the added uptick in manufacturing complexity because its vehicle assembly is "inherently less complex." A company spokesperson tells us that Slate has just 500 end-items—a manufactured component ready to install as part of the assembly process—delivered to its plant for vehicle production.

Most car factories have around 2,500 unique end-items for each vehicle, according to Slate. Fewer parts work out to a lower cost per minute, which means that Slate can repurpose some of that saved cost into the time that would be reduced by Gigacasting.

The Slate Truck Won't Use Gigacasting. Here's Why It Doesn't Need It

Slate is all about reducing costs by reducing complexity, so why isn't it using Gigacasting?

A car is built using a ton of stamped parts. To create these parts, a sheet of metal is fed into a machine that sandwiches it between a die and squeezes it until it forms a specific shape. This is great for smaller parts, but when you're building something larger (like the underpinnings of a vehicle), these pieces may need to be fastened together using rivets or welding.

Gigacasting, on the other hand, is taking molten metal and using a High-Pressure Die Casting (HPDC) machine to force the liquid metal into a mold. Tesla pioneered this technology and remains arguably its most vocal proponent, but the rest of the auto industry is rapidly chasing it too.

It allows for the creation of complex metal parts without the need to manually fasten each individual stamped part one by one. In Tesla's case, gigacasting allowed Tesla to eliminate 370 parts from the Model Y, all while reducing weight by 10% and improving efficiency.

171 stamped parts and 1,600 welds were eliminated by the use of two parts created by Gigacasting.

One key metric in automotive manufacturing is cost per minute. That figure is the time it takes a worker or piece of machinery to change the form, fit, or function of a vehicle. You know the saying "time is money"? It's extremely true in manufacturing and is something that automakers are willing to pay industrial engineers big bucks to cut down on.

Gigacasting reduces that cost significantly by optimizing equipment (think reducing the number of robots needed to assemble panels or welders to fasten them together), factory space, and even enabling waste to be easily recycled.

That's the good, but what about the bad? Well, that all comes down to cost—and that's where Slate looked at the tech and shook its head

"Gigacasting takes out complexity in parts but adds complexity in engineering and cost," a Slate spokesperson told InsideEVs. "Slate engineering and manufacturing focused on taking out what’s unnecessary and delivering a radically affordable vehicle."

Translation: We don't need a fancy metal-squirting machine to solve a problem we didn't already have.

Slate says it can justify the added uptick in manufacturing complexity because its vehicle assembly is "inherently less complex." A company spokesperson tells us that Slate has just 500 end-items—a manufactured component ready to install as part of the assembly process—delivered to its plant for vehicle production.

Most car factories have around 2,500 unique end-items for each vehicle, according to Slate. Fewer parts work out to a lower cost per minute, which means that Slate can repurpose some of that saved cost into the time that would be reduced by Gigacasting.