-

👉 Slate Reservations Tracking List: Add Your Slate Reservation 📊

New Video: Seeing the Slate Truck in Person - Reality Check

The Dude

Well-Known Member

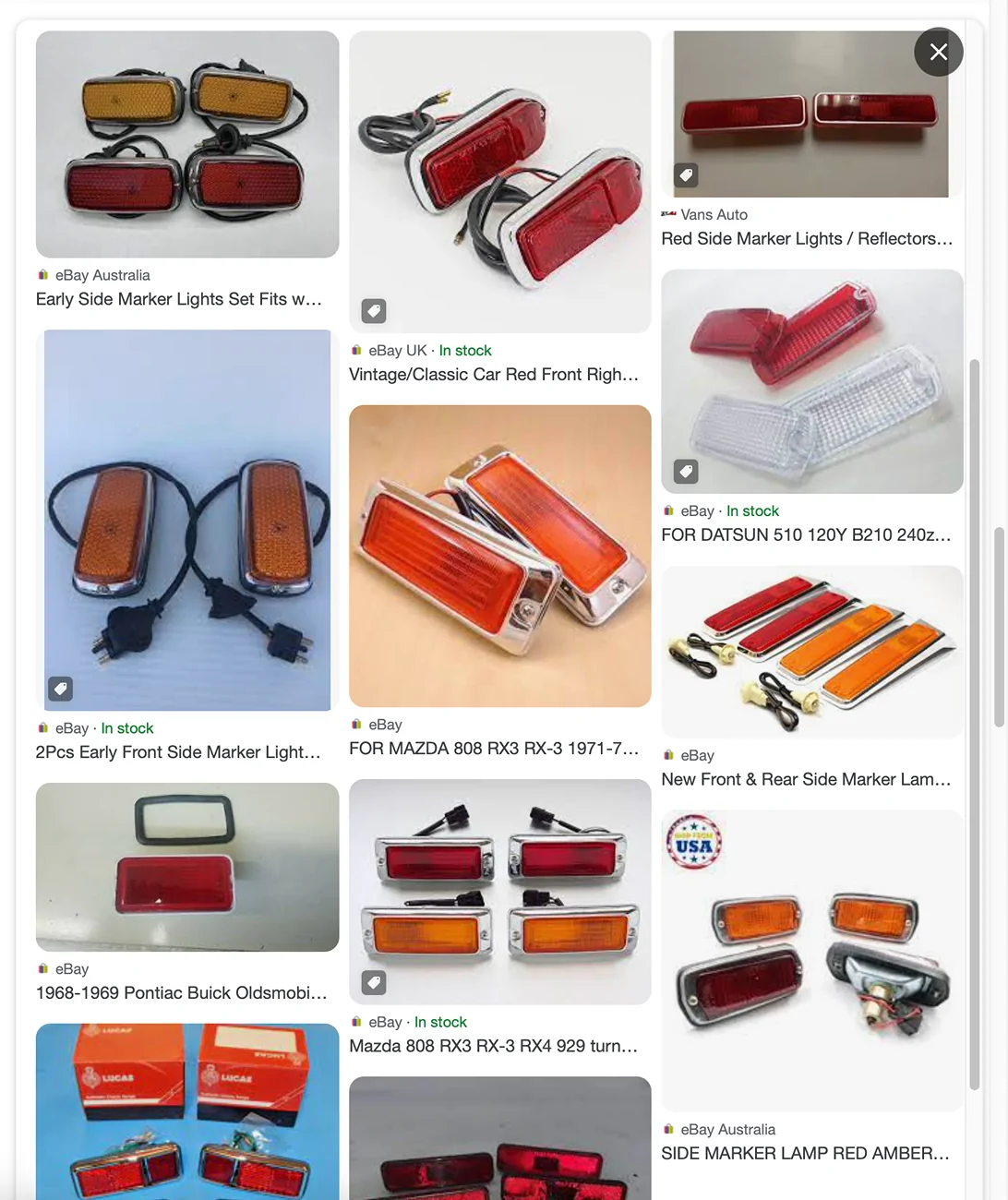

Thanks for the clear video. Wow. Starting to see a lot of thing Im going to have to fix once it's in the driveway. Im just to picky. First thing is lining everything up. Definitely replacing the markers with ones that go over the panel held with screws. Not the other way around. And a lot of adhesive and weather stripping.

sodamo

Well-Known Member

- First Name

- David

- Joined

- May 19, 2025

- Threads

- 7

- Messages

- 737

- Reaction score

- 770

- Location

- Big Island Hawaii

- Vehicles

- Tundra 1794, Subaru Ascent

Would you advise waiting until actually in the yard before investing in too much stuff.Thanks for the clear video. Wow. Starting to see a lot of thing Im going to have to fix once it's in the driveway. Im just to picky. First thing is lining everything up. Definitely replacing the markers with ones that go over the panel held with screws. Not the other way around. And a lot of adhesive and weather stripping.

nstrains10

Member

- First Name

- Cody

- Joined

- May 30, 2025

- Threads

- 2

- Messages

- 16

- Reaction score

- 52

- Location

- Mechancisburg, PA

- Vehicles

- 2014 Ford Focus, 2021 Chevy Suburban

I'm sure a lot of the alignment stuff will be cleaned up on the production models. As for the markers, that's a different story. Haha There was a thread somewhere on here about changing the lenses to clear on those as well.

The Dude

Well-Known Member

I am. But Im good with fabricating stuff with cars. From what I have seen so far. I would not trust these guys at wrapping the truck. Imagine the head ache of receiving a wrapped vehicle that you weren't happy with. But we'll see.Would you advise waiting until actually in the yard before investing in too much stuff.

Last edited:

Luxrage

Well-Known Member

- Joined

- Apr 28, 2025

- Threads

- 4

- Messages

- 349

- Reaction score

- 463

- Location

- Sherman, TX

- Vehicles

- 1993 Geo Tracker, 1989 Ford Country Squire, 2007 Honda Element, 2011 Honda Fit

I'm sure a lot of these fitment issues will be ironed out by the time they're making these full production. Especially that frunk shot where it looks like they dremel'd out more plastic for clearance.

Doctors Do Little

Well-Known Member

You know, I saw a full size truck this morning with a bed step built into the rear quarter panel, and I was thinking that this would be a pretty easy thing to do on the Slate....cut a hole in the rear quarter panel and grab one of the many steps out there and as long as there is somewhere to fasten it to something solid (frame?), you'd be set to have a quick step into the back...with your skills, this would be easy. (For me, I'd have to measure, measure, pray, cut, cuss, cut some more, and then fasten and fit.)I am. But Im good with fabricating stuff with cars. From what I have seen so far. I would not trust these guys at wrapping the truck. Imagine the head ache of receiving a wrapped vehicle that you weren't happy with. But we'll see.

evtruth

Well-Known Member

- First Name

- Bobbie

- Joined

- May 30, 2025

- Threads

- 4

- Messages

- 123

- Reaction score

- 196

- Location

- Warsaw, IN

- Website

- www.youtube.com

- Vehicles

- 2025 Tesla Model Y Performance, 2025 Chevrolet Silverado EV

People keep forgetting these **are not** production trucks. A lot of fit and finish things will be ironed out in production.Thanks for the clear video. Wow. Starting to see a lot of thing Im going to have to fix once it's in the driveway. Im just to picky. First thing is lining everything up. Definitely replacing the markers with ones that go over the panel held with screws. Not the other way around. And a lot of adhesive and weather stripping.

motorolas

Well-Known Member

Million dollar hand made prototypes going to have rough edges.

Slate broke ground on assembly plant and expect to see finished builds sometime next fall/winter. The wait from now to then will be boring

Slate broke ground on assembly plant and expect to see finished builds sometime next fall/winter. The wait from now to then will be boring

The Dude

Well-Known Member

Here! Id like to sell you this for Thousands of dollars. I know it's cobbled together and has a lot of work left to do. But trust me. It'll look WAY more better than what Im showing you right now. 😉 Just saying. Me and a bunch of other guys could take what they are displaying and make it look WAY more presentable. Maybe that's why they stopped doing the events.These units were cobbled together from non-production parts, tooling, and engineering... WTF are people expecting to see here?

Dorbiman

Well-Known Member

Sounds like you should offer your services to Slate Auto. I'm sure they'd be quite impressed with your capabilitiesHere! Id like to sell you this for Thousands of dollars. I know it's cobbled together and has a lot of work left to do. But trust me. It'll look WAY more better than what Im showing you right now. 😉 Just saying. Me and a bunch of other guys could take what they are displaying and make it look WAY more presentable. Maybe that's why they stopped doing the events.

motorolas

Well-Known Member

I’m impressed they had 70+ units for testing and certification.Here! Id like to sell you this for Thousands of dollars. I know it's cobbled together and has a lot of work left to do. But trust me. It'll look WAY more better than what Im showing you right now. 😉 Just saying. Me and a bunch of other guys could take what they are displaying and make it look WAY more presentable. Maybe that's why they stopped doing the events.

There were rougher units that were doing testing in Arizona a few months ago. Looking forward to Slate showing final products off next year if they can get there. It’s tough to make things for sure.

Similar threads

- Replies

- 3

- Views

- 784

- Replies

- 2

- Views

- 433

- Replies

- 0

- Views

- 263

- Replies

- 6

- Views

- 890

Similar threads

- Replies

- 30

- Views

- 2,798