AZFox

Well-Known Member

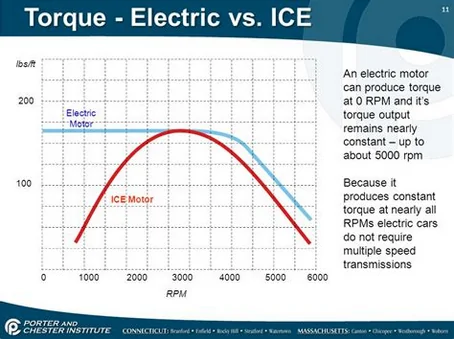

Seriously?[201 HP and 195 TQ may not be enough. for h]auling and towing.

You're saying 195 pound-feet isn't enough to tow (up to) 1,000 pounds?

My '89 S-10 had the 4.3L V6 (essentially a Chevy 350 Small Block with two cylinders removed).

I never felt the truck needed more power. It was quite the opposite because I enjoyed having a powerful small pickup.

A Slate Truck would probably beat that S-10 in a drag race.