Firstevexcited1

Active Member

- Thread starter

- #1

What company or factory will be building the frame of the truck? Will it be powder coated? Some kind of weather protection I'm hoping.

I would think it’s best to build them on site, most cost productive,What company or factory will be building the frame of the truck? Will it be powder coated? Some kind of weather protection I'm hoping.

Typically railroads ship truck frames in to domestic auto plants via flat car. Since this is more of a unibody design I imagine it will be assembled at the plant in Warsaw. Perhaps ingredients of the unibody assembly are manufactured elsewhere and shipped in for final assembly at Warsaw? On domestic manufacturers railroads supply a lot of parts via box cars in to the plant and take the finished autos out on auto racks.(flat cars with an auto carrier mounted on top with 2 or 3 levels, bi-levels or tri-levels). On foreign manufacturers the suppliers are usually located much closer to the plant and are trucked in to the plant and the railroads handle the finished autos out.What company or factory will be building the frame of the truck? Will it be powder coated? Some kind of weather protection I'm hoping.

Warsaw plant has several train tracks leading to both sides of the building. Google maps has already changed the name on it to SLATE.Typically railroads ship truck frames in to domestic auto plants via flat car. Since this is more of a unibody design I imagine it will be assembled at the plant in Warsaw. Perhaps ingredients of the unibody assembly are manufactured elsewhere and shipped in for final assembly at Warsaw? On domestic manufacturers railroads supply a lot of parts via box cars in to the plant and take the finished autos out on auto racks.(flat cars with an auto carrier mounted on top with 2 or 3 levels, bi-levels or tri-levels). On foreign manufacturers the suppliers are usually located much closer to the plant and are trucked in to the plant and the railroads handle the finished autos out.

Google maps has changed the name already on the factory to Slate. Has several train tracks...looks promising.Our local Toyota plant in Southern IN (currently building Lexus I've been told) gets their frames shipped in. They have train tracks, but in the past, I also saw them being trucked in. I don't know where they are made. This is where they started making Tundras.

The equipment to put this complicated frame together (flat panel laser,arbor presses,punch presses, robot welders and full powder coat line) would take a lot of money up front. I would think it would be more cost effective to out. source..just my thought.Slate’s facility in Warsaw is 1.4 million square feet. Even though they negotiated a phenomenal deal for real estate tax incentives, their lease payment is still somewhere between $100k - $200k per month. If I was on Slate’s operations team I would expect that the factory do as much fab and assembly as possible in house to contain costs. That includes frames and coatings, composites, controls, electronics and all other subs and major components. (There was a recent job post on LinkedIn for a coatings engineer at Warsaw). Most “make /buy” decisions (other than batteries) should be fairly straightforward. Certainly, filling up the factory is a phased approach and more production lines will be added beyond 2027. So we should expect A LOT of work performed in house at Indiana.

The Toyota frames most likely being shipped in from another Toyota owned facility. Toyota’s excellent quality control and reliability is primarily due to tight controls over in house processes.Our local Toyota plant in Southern IN (currently building Lexus I've been told) gets their frames shipped in. They have train tracks, but in the past, I also saw them being trucked in. I don't know where they are made. This is where they started making Tundras.

I agree. The goal right now is to get production off the ground, the sooner they can get truck going out the door the quicker they can start making money.The equipment to put this complicated frame together (flat panel laser,arbor presses,punch presses, robot welders and full powder coat line) would take a lot of money up front. I would think it would be more cost effective to out. source..just my thought.

Maybe 100% robotic welding for the space frame?I think the frame sheet metal and hydro formed rail parts and pieces will be manufactured at outside suppliers and assembled (welded together into the spaceframe) and power coated in the Warsaw facility. 1.4M sq ft is a large enough space to house 300 vehicles per shift on an assembly line. I've worked in a manufacturing plant of that size as a equipment planning engineer, that is a lot of space to use for assembly.

Based on what I've heard and read, I'd bet the front and rear suspensions will come fully assembled and bolt-in ready from suppliers. Cable harnesses outsourced. Body panels from a supplier. Battery assembled in-house and a sourced electric motor. Glass and seats from suppliers.

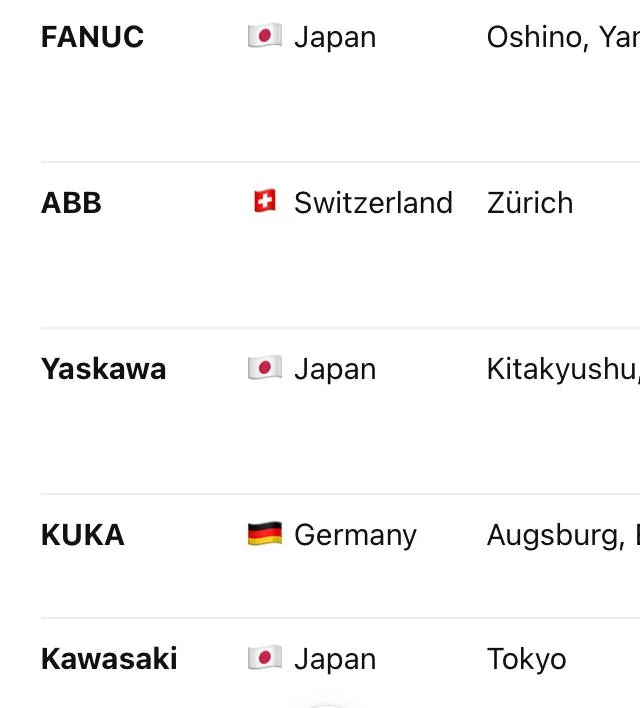

According to ChatGPT, these are the leading robotic automation companies:I'd think so.